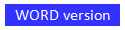

The piston moves downwards carried by the

inertia of the flywheel, and the petrol/air mixture is sucked into the

cylinder through the open inlet valve. The outlet valve is closed.

The

petrol air mixture is quite cold at this point, its temperature depends on

the air temperature outside the engine.

Notice the piston rings, these

help to seal the cylinder.

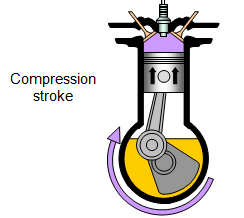

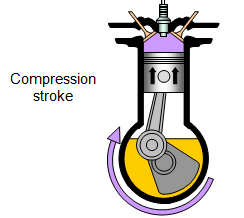

The flywheel

moves round, pushing the piston up and so compressing the mixture in

the cylinder. As it does so the mixture will warm up a little depending on

how much it is compressed. Both the valves are closed during this

stroke.

The ratio of the volume of the cylinder when the piston is fully

down to that when it is fully up is called the compression ratio, usually

about eight.

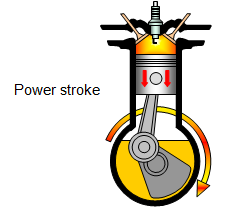

When the piston reaches its

highest position the spark plug fires. At this point the mixture has its

smallest volume and when it is ignited by the spark it expands and this

forces the piston rapidly down the cylinder.

Both valves are closed

during this stroke.

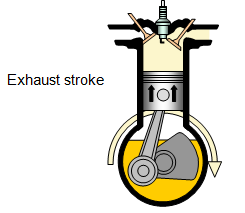

As the piston

moves up again the burnt gases are forced out of the open exhaust

valve. The inlet valve stays shut.

Because the petrol/air mixture is

burnt in the enclosed cylinder with a limited amount of air the burning is

not very efficient.

In the diesel

engine there are no sparking plugs. The compression ratio is very large, up to 15:1, and the

fuel is pumped into the cylinder as a fine spray.

On the compression stroke the fuel/air

mixture is compressed so much that it heats up a great deal. It is so hot that it catches fire on

its own without the need for a spark.

Diesel engines have a heater to heat them up on

starting and they are also rather heavy because the cylinders have to withstand high

pressures. However, they are very reliable and have a higher efficiency than other petrol

driven internal combustion engines.